The laser welding machine is a proficient and exact welding technique that utilizes a high-energy thickness laser bar as a hotness source. The welding system is of warm conductivity type. Laser radiation warms the outer layer of the workpiece, and the surface hotness diffuses into the inside through warm conduction.

The workpiece is softened to frame a particular liquid pool by controlling the width, energy, maximum power, and redundancy recurrence of the laser beat. The laser welding machine can successfully consolidate the weld’s atomic layers and understand the weld’s consistent joint. So what would the handheld laser welder be utilized for, and how can it function?

Utilization of modern laser welding machines:

1. Vehicle fabricating industry.

The vehicle business is one of the principal application areas of laser welding hardware. Whenever a vehicle is driving, it will lose contact with the ground. Each part and design is exposed to changing levels of effect, which requires the general underlying thickness of the vehicle to help. In the auto business, laser welding is typically utilized in crucial places of body welding and parts with exceptional prerequisites for interaction.

2. Kitchenware industry

The fiber laser welding machine takes on high-power consistent welding to make more delightful hardened steel kitchenware and address individuals’ issues, and the impact is better. The machine needn’t bother with any consumables, and the activity is essential and advantageous.

Laser welding machining innovation is a non-contact handling technique, so there is no automatic expulsion or mechanical pressure. The creation of cooking wares has moderately high prerequisites for welding innovation, and the conventional welding process is complex to meet the high-accuracy creation necessities.

3. Entryway and window guardrail handling industry

There is something else and more hardened steel materials during the time spent on current home improvement, including some treated steel entryways, windows, and guardrails. The tempered steel entryways, windows, and guardrails likewise should be welded with welding hardware during the process.

The handheld laser welder can significantly decrease the readiness of workpieces in the beginning phase of welding and lessen the technical necessities for welding operators. We need to change the welding boundaries as indicated by the thickness of hardened steel entryways and windows. The handheld laser welding machine has a solid infiltrating capacity, the welding appearance is perfect and excellent, and the welding strength is better.

How do modern laser welding machines work?

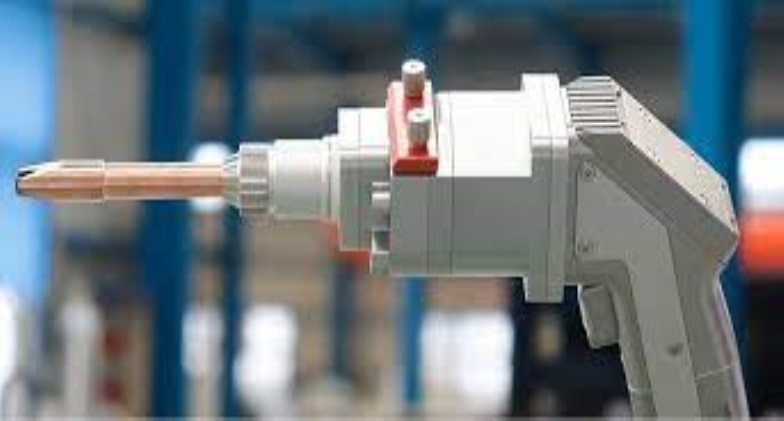

JNCT LASER handheld laser welding machine has six spot modes, which can all the more likely; adjust to the various workpiece handling necessities.

Point mode alludes to the state where the engine isn’t swinging, and the light spot is the littlest. Solid infiltrating power can be utilized for entrance welding, fasten welding, or thicker materials.

Straight mode: alludes to swing an engine, draw an obvious conclusion into a line, change the width, and have a specific entrance power to thick plates. It is reasonable for filet welding, tailor welding, and wire feed welding.

Round mode: swings two engines to make the dab edges into a circle. The distance across can be changed. The energy thickness is equally disseminated. The benefit of utilizing high recurrence welding of thin plates is self-evident. It very well may be utilized for welding dainty plates with a base thickness of 0.3mm.

Laser head recurrence: the higher the recurrence, the quicker the engine pivot speed. The spots are thick, yet the single-point energy is somewhat more vulnerable. It is appropriate for flimsy plate welding and isn’t difficult to enter the plate. The low-recurrence engine pivots gradually, and the light spot layout shows clear and solid energy, which is reasonable for thick plate welding.

Laser head width: The welding width goes from 0.2 to 5mm. The welding width is not entirely set in stone, as indicated by the size of the plate hole and the distance across the welding wire. The bigger the welding width, the more extensive the laser range, and the energy will be somewhat scattered.