Fibre developments

The evolution of fibre developments has gone through the phases of conventional fibres, highly functional fibres and high-performance fibres. Polyester is the single most common fibre used for sportswear and active wear. Other fibres suitable for active wear are polyamide, polypropylene, acrylics and elastanes. Wool and cotton fibres are still finding applications in leisurewear. Synthetic fibres can either be modified during manufacture, e.g. by producing hollow fibres and fibres with irregular cross-section, or be optimally blended with natural fibres to improve their thermo-physiological and sensory properties.

High-performance fibres

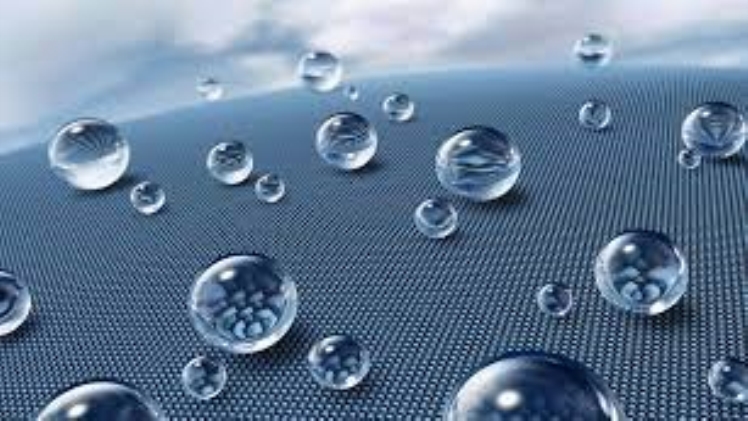

A wide range of high-performance fibres is commercially available Custom Teamwear for technical and industrial applications. These types of fibres are used in sports protective wear equipment developed for impact protection and in textile reinforcement in sports products for different applications. Synthetic fibres with improved UV resistance and having anti-microbial properties are also commercially available for use in sportswear. Improved fibre spinning techniques in melt spinning, wet spinning, dry spinning as well as new techniques such as gel spinning, bi-component spinning and microfiber spinning, have all made it possible to produce fibres, yarns and fabrics with unique performance characteristics suitable for use in sportswear and sports goods.

Conclusion

By using the conjugate spinning technique, many different types of sophisticated fibres with various functions have been commercially produced which has resulted in fabrics having improved mechanical, physical, chemical and biological functions. The technique of producing sheath/core melt spun conjugate fibres has been commercially exploited for producing added-value fibres. Unitika produced the first heat-regenerating conjugate fibre with a core containing zirconium carbide. Since ZrC absorbs sunlight and emits far-infrared radiation, one feels warmer when one puts on a jacket made from such fibres. Other types of heat-generating fibres contain ceramic micro-particles. Read more about: pagalworld

Read more about f95zone